660 A/B/C/D

Density: 7.93 g/cm³

Equivalent designations:

Incoloy A286, A-286, AISI/ASTM 660, DIN W.NR 1.4943

Available products:

pipe,tube,bar,rod,wire,sheet,strip,fastener,bolt and nut,pipe fittings

Product introduction

Alloy 660 is a precipitation hardening austenitic stainless steel known for its impressive strength at high temperatures up to 700°C. Also called the names as UNS S66286, and A-286 alloy. Alloy 660 gains its strength from a high degree of uniformity. It has an impressive yield strength minimum of 105,000 psi and is commonly used in high temperature fastening and bolting materials.

Applications:

1. High temperature fastening and bolting materials

2. Jet engines

3. Gas turbines

4. Turbo charger components

Chemical composition:

Applications:

1. High temperature fastening and bolting materials

2. Jet engines

3. Gas turbines

4. Turbo charger components

Chemical composition:

| Grade | Chemical Component % | |||||||||||

| Ni | Cr | Ti | Mn | Mo | Si | V | Al | C | P | S | B | |

| 660 | 24.0-27.0 | 13.5-16.0 | 1.9-2.35 | Max 2.0 | 1.0-1.5 | Max 1.0 | 0.1-0.5 | Max 0.35 | Max 0.0.8 | Max 0.04 | Max 0.03 | Max 0.01 |

Different between 660A, 660B, 660C, 660D:

| Grade | Class | Solutiona Treatment | Hardening Treatment | ||||||

| 660 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool | ||||||

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool | |||||||

| C | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and oil quench | 1425 +/- 25 °F [775 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool | |||||||

| D | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool | |||||||

| Grade | Class | Tensile Strength, Mpa | Yield Strength (0.2%), Mpa | Elongation %, min | RA %, min | ||||

| Gr 660 | A, B , & C | 895 min | 585 min | 15 | 18 | ||||

| Gr 660 | D | 895 min | 725 min | 15 | 18 | ||||

Available products fo 660:

Welded pipe/tube

Seamless pipe/tube

Pipe fittings

Flanges

Bar/Profiles

Sheet/ Plate/Coil/Strip

Wire/Wire rope

Forgings

Welding Rod

Bolt and Nut

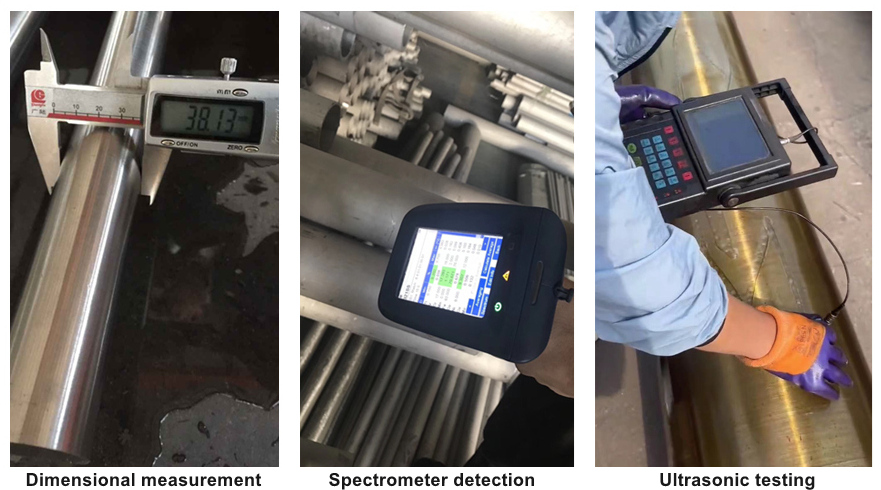

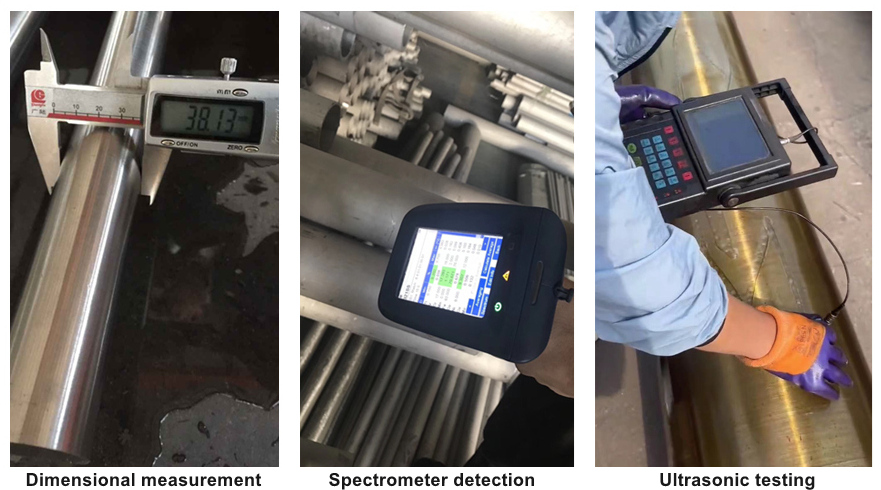

Test before shipping:

Welded pipe/tube

Seamless pipe/tube

Pipe fittings

Flanges

Bar/Profiles

Sheet/ Plate/Coil/Strip

Wire/Wire rope

Forgings

Welding Rod

Bolt and Nut

Test before shipping:

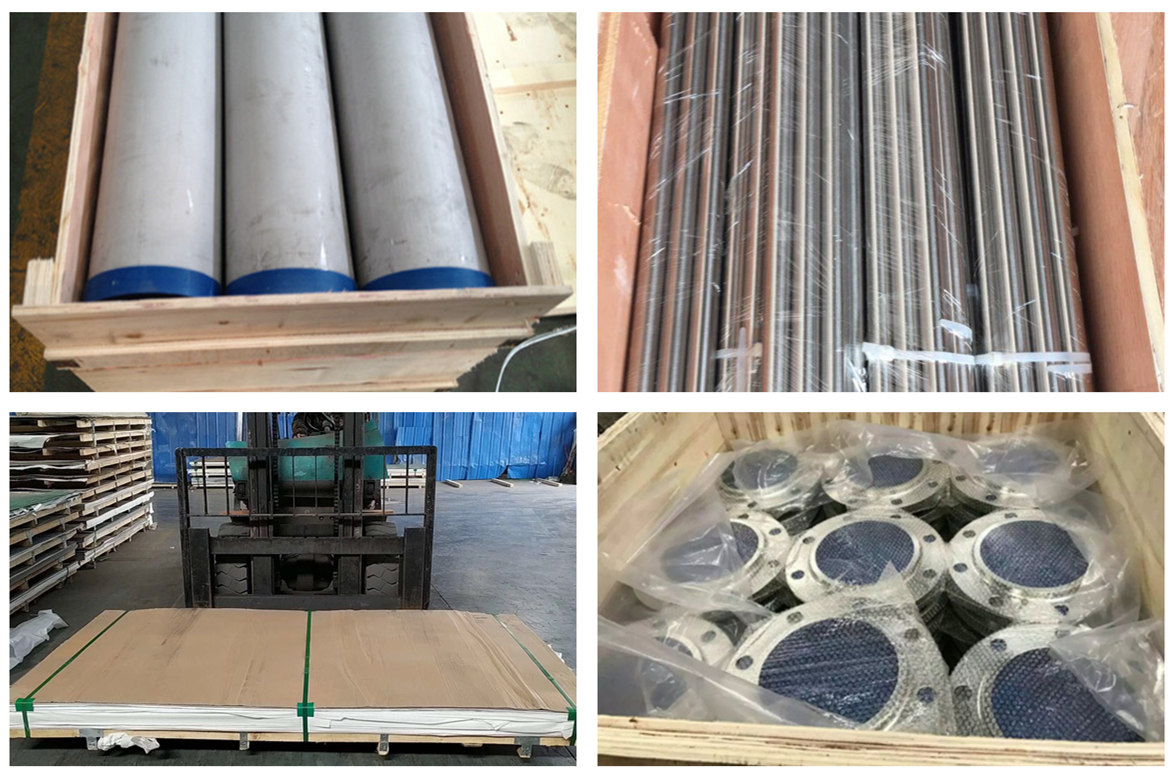

Cargo packaging: