ASTM A249 stainless steel welded tubes for boilers, superheaters, heat exchangers and condensers

OD: 1/8 in. [3.2 mm] to 12 in. [304.8 mm]

WT: 0.015 to 0.320 in. [0.4 to 8.1 mm]

Length: 1-12m

Surface:180grit,240 grits,400grit,600grit , 1D,2B,NO.4,6K,8K,hairline, satin and mirror finish

Packing: woven bags, wooden box,iron box or as required

Product introduction

ASTM A249 stainless steel welded tube for boiler, superheater, heat exchanger, or condenser is one of the most advantage type in Chanson Metals’ products line.

Grades: TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP316H, TP321H, TP347H, and TP348H are modifications of Grades TP304, TP309S, TP309Cb, TP310S, TP310Cb, TP316, TP321, TP347, and TP348, and are intended for high-temperature service such as for superheaters and reheaters.

| HS Code | 7306400000 |

| Standard | ASTM, ASME, DIN, EN, ISO,JIS, GOST, etc. |

| Produce process | Automatic welding (submerged arc welding, plasma welding), manual welding (argon arc welding) |

| Marking | Grade+Type+Standard+Size+Heat NO or as required |

| Price Term | EX-Work, FOB, CFR, CIF,CNF |

| OEM | Accepted |

| Payment term | T/T,L/C, Western union |

| Certificate | ISO 9001, PED |

| Third party inspection | Accepted |

Chemical composition under ASTM A249:

| Grade | UNS | Chemical Component % | ||||||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu | Other | ||

| TP201 | S20100 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 3.50-5.50 | 16.0-18.0 | 0.25 | |||

| TP202 | S20200 | 0.15 | 7.50-10.0 | 0.06 | 0.03 | 1 | 4.0-6.0 | 17.0-19.0 | 0.25 | |||

| TPXM-19 | S20910 | 0.06 | 4.0-6.0 | 0.45 | 0.03 | 1.00 | 11.5-13.5 | 20.5-23.5 | 1.5-3.0 | 0.2-0.4 | - | Nb:0.10-0.30 V:0.10-0.30 |

| TPXM-29 | S24000 | 0.08 | 11.5-14.5 | 0.06 | 0.03 | 1.00 | 2.3-3.7 | 17.0-19.0 | - | 0.2-0.4 | - | - |

| TP304 | S30400 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-11.0 | 18.0-20.0 | - | - | - | - |

| TP304L | S30403 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-12.0 | 18.0-20.0 | - | - | - | - |

| TP304H | S30409 | 0.04~0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-11.0 | 18.0-20.0 | - | - | - | - |

| TP304N | S30451 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-11.0 | 18.0-20.0 | - | 0.10-0.16 | - | - |

| TP304LN | S30453 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-11.0 | 18.0-20.0 | - | 0.10-0.16 | - | - |

| S30815 | 0.05-0.10 | 0.80 | 0.04 | 0.03 | 1.4-2.00 | 10.0-12.0 | 20.0-22.0 | 0.14-0.20 | Ce 0.03-0.08 | |||

| TP309S | S30908 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 12.0-15.0 | 22.0-24.0 | - | - | - | |

| TP309H | S30909 | 0.04~0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 12.0-15.0 | 22.0-24.0 | - | - | - | |

| TP310S | S31008 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 19.0-22.0 | 24.0-26.0 | - | - | - | |

| TP310H | S31009 | 0.04~0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 19.0-22.0 | 24.0-26.0 | - | - | - | |

| S31254 | 0.02 | 1.00 | 0.03 | 0.01 | 0.80 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | 0.18-0.25 | 0.50-1.00 | - | |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | - | - | - |

| TP316L | S31603 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | - | - | - |

| TP316H | S31609 | 0.04~0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | - | - | |

| TP316N | S31651 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 10.0-13.0 | 16.0-18.0 | 2.00-3.00 | 0.10-0.16 | - | - |

| TP316LN | S31653 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 10.0-13.0 | 16.0-18.0 | 2.00-3.00 | 0.10-0.16 | - | - |

| TP317 | S31700 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.00-4.00 | - | - | - |

| TP317L | S31703 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.00-4.00 | - | - | - |

| TP321 | S32100 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 9.0-12.0 | 17.0-19.0 | - | 0.1 | - | Ti5(C+N)~0.7 |

| TP321H | S32109 | 0.04~0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 9.0-12.0 | 17.0-19.0 | - | 0.1 | - | Ti4(C+N)~0.6 |

| S32654 | 0.02 | 2.0-4.0 | 0.03 | 0.005 | 0.50 | 21.0-23.0 | 24.0-25.0 | 7.0-8.0 | 0.45-0.55 | 0.30-0.60 | - | |

| TP347 | S34700 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 9.0-12.0 | 17.0-19.0 | - | - | - | Nb:10*C%-1.1 |

| TP347H | S34709 | 0.04~0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 9.0-12.0 | 17.0-19.0 | - | - | - | Nb:8*C%-1.0 |

| TP348 | S34800 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 9.0-12.0 | 17.0-19.0 | - | - | - | Nb+Ta:10*C%-1.0,Ta:0.10 Co:0.20 |

| TP348H | S34809 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 9.0-12.0 | 17.0-19.0 | - | - | - | Nb+Ta:10*C%-1.0,Ta:0.10 Co:0.20 |

| N08904 | 0.02 | 2.00 | 0.04 | 0.03 | 1.00 | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 | 0.1 | 1.0-2.0 | - | |

| N08926 | 0.02 | 2.00 | 0.03 | 0.01 | 0.5 | 24.0-26.0 | 19.0-21.0 | 6.0-7.0 | 0.15-0.25 | 0.50-1.50 | - | |

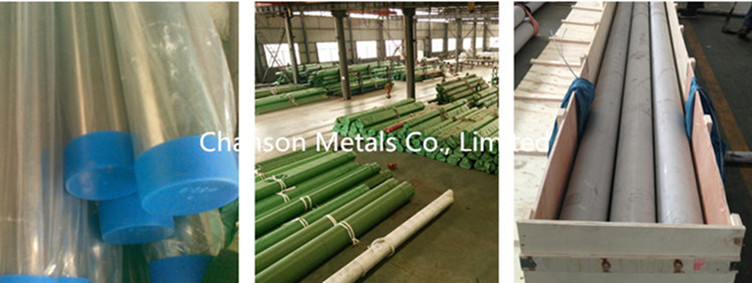

Stainless steel pipe packing:

Production line and warehouse:

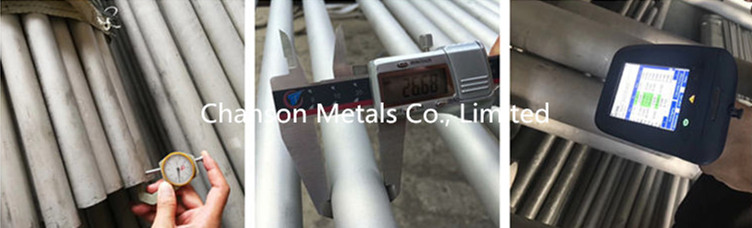

Stainless steel pipe test: